Software Managed Compressor

|

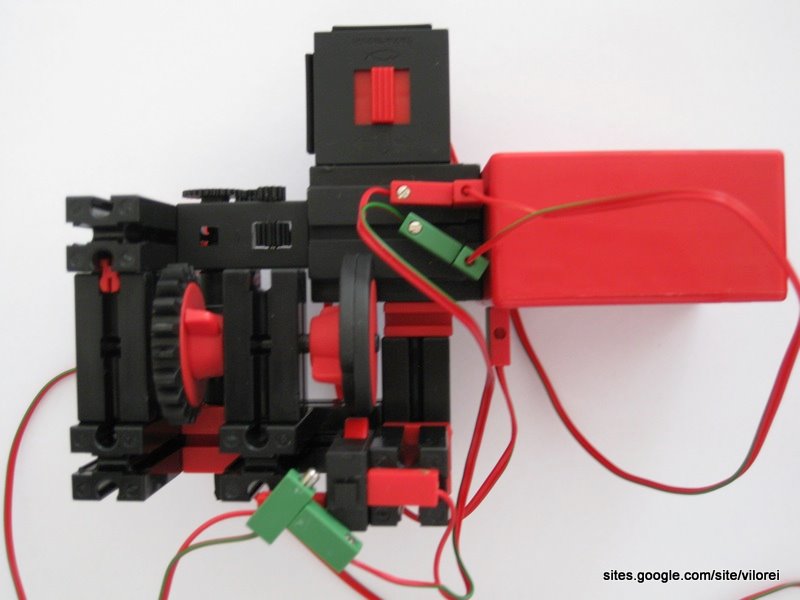

A common problem I'm facing with models including compressed air, is managing the balance between supply and demand.

If supply exceeds demand, the motor runs with difficulty and speeds-up tear-down, despite the rubber band.. Otherwise, too low supply and the cylinders don't work fast enough and long enough or, worst, object falls in case of the use of a vacuum head. Let's evaluate four solutions: |

1. Time Based Supply

2. Sensor Monitored Supply

|

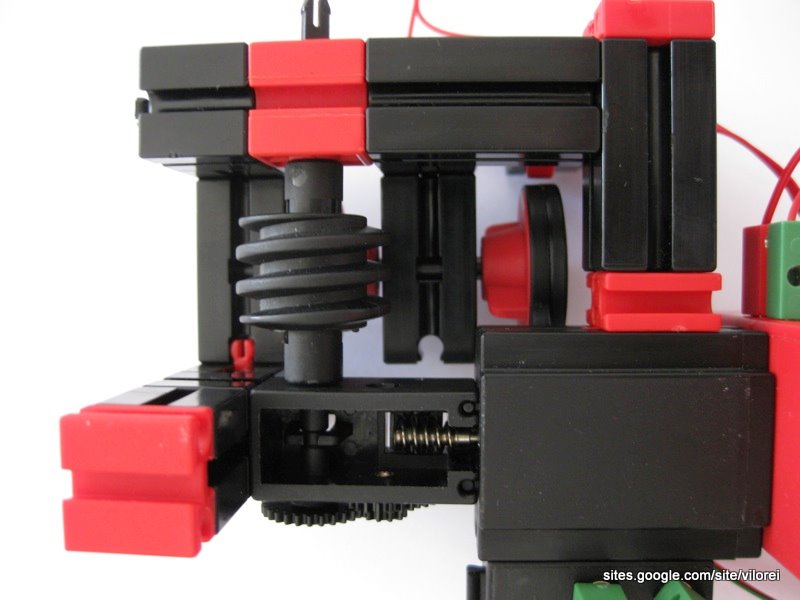

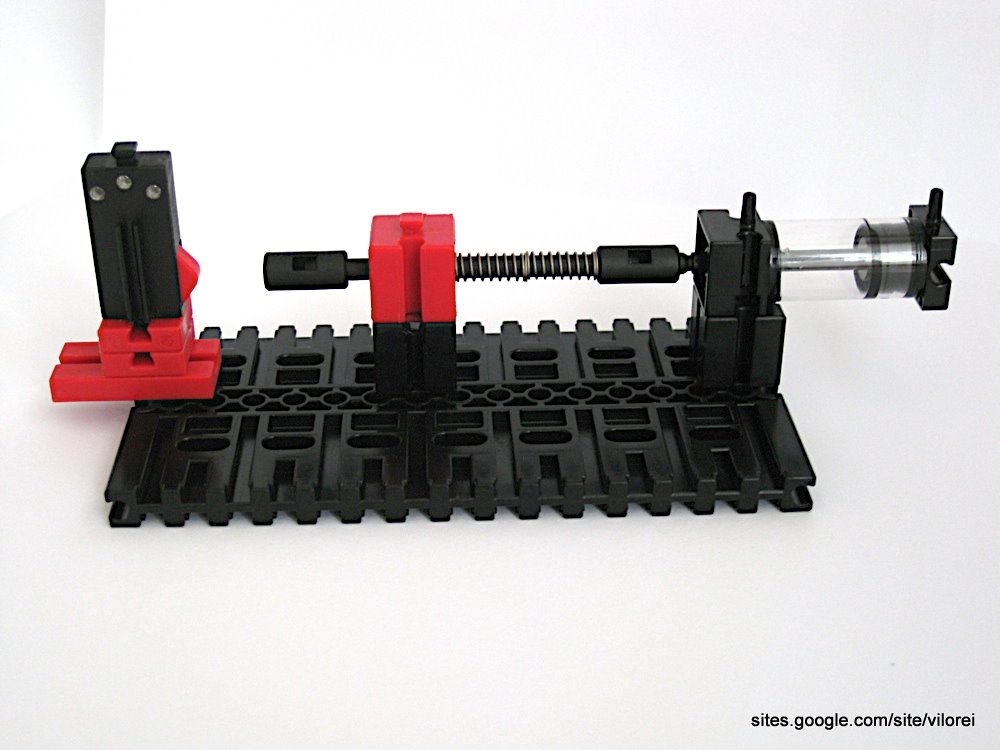

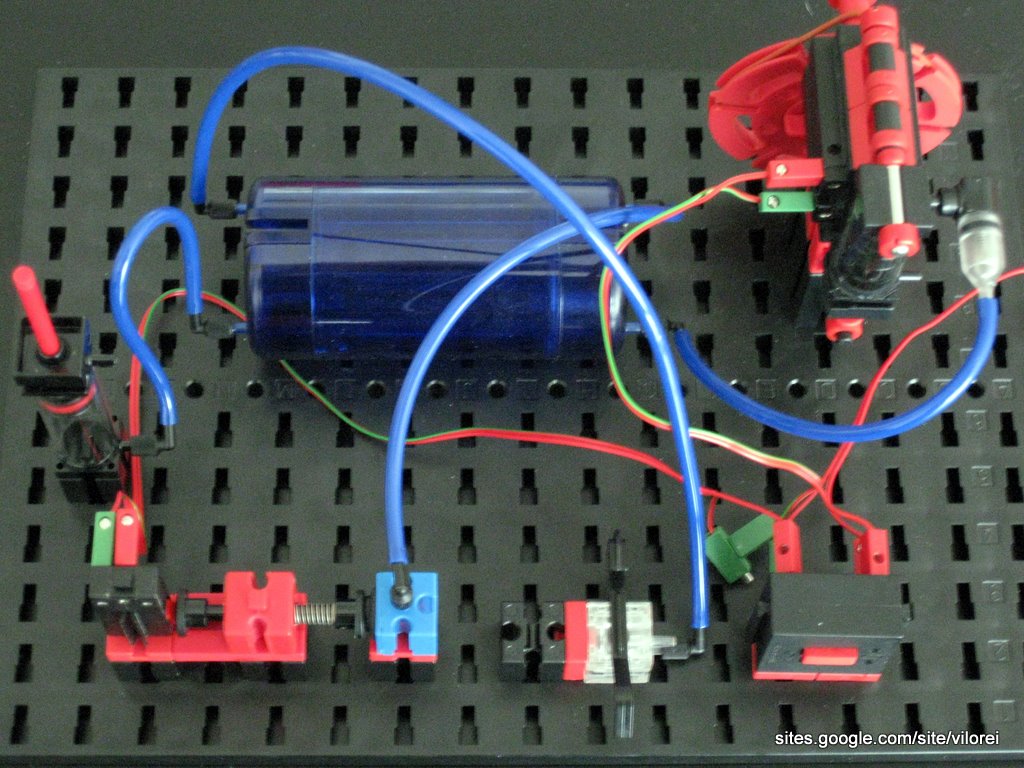

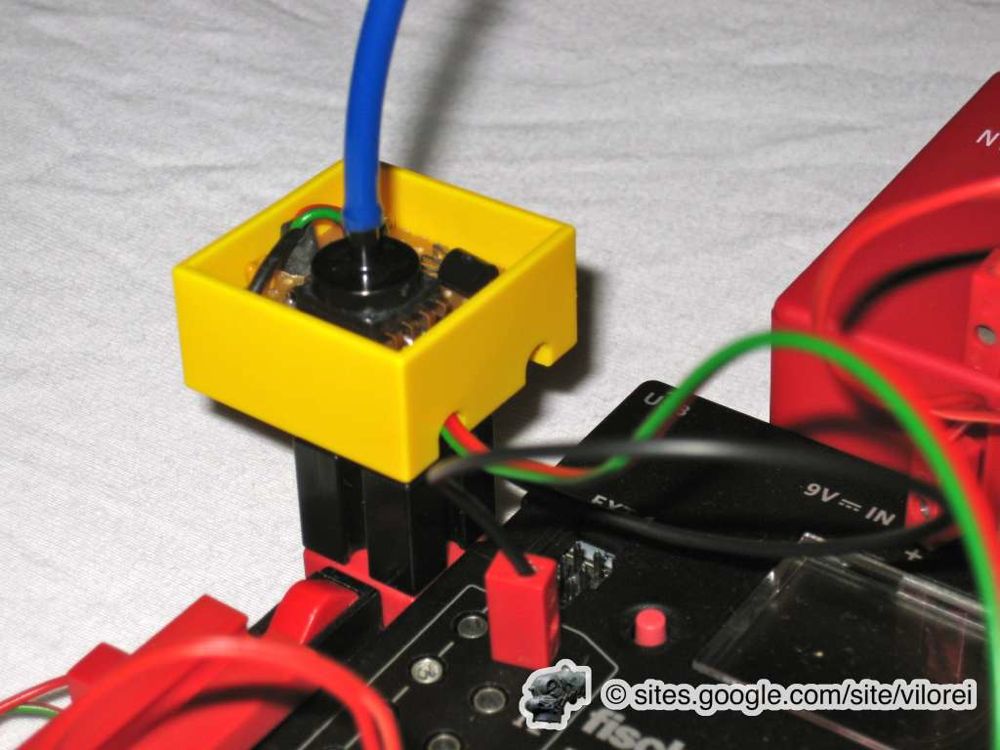

When use of compressed air is not regular, using a sensor could provide an efficient solution.

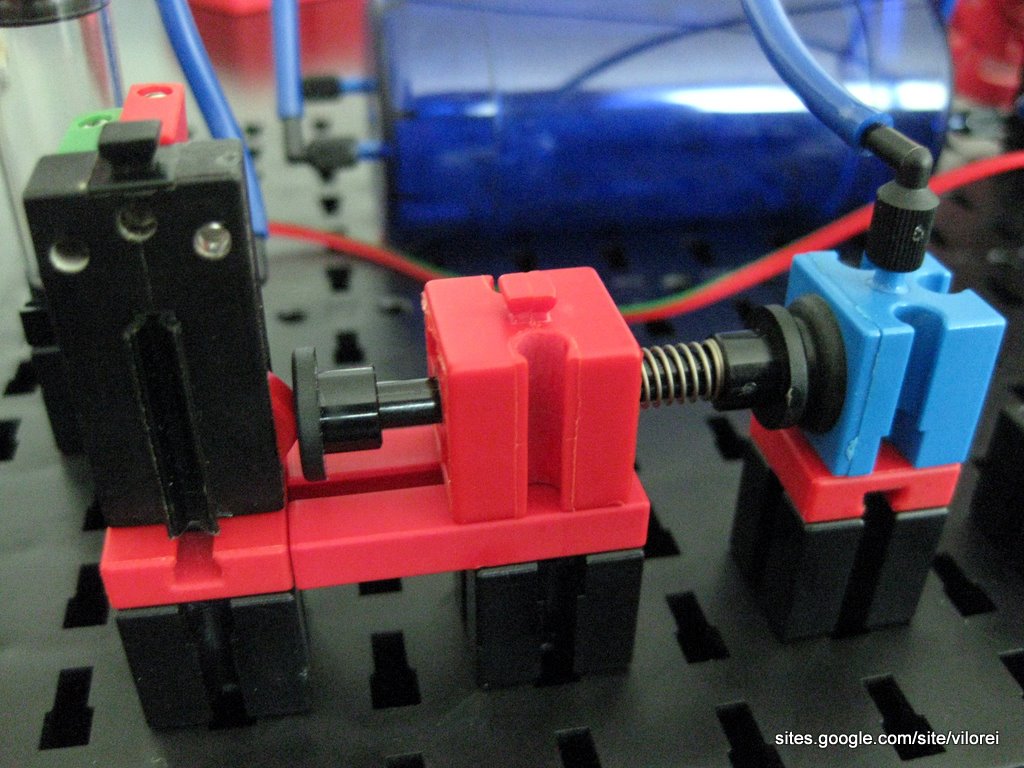

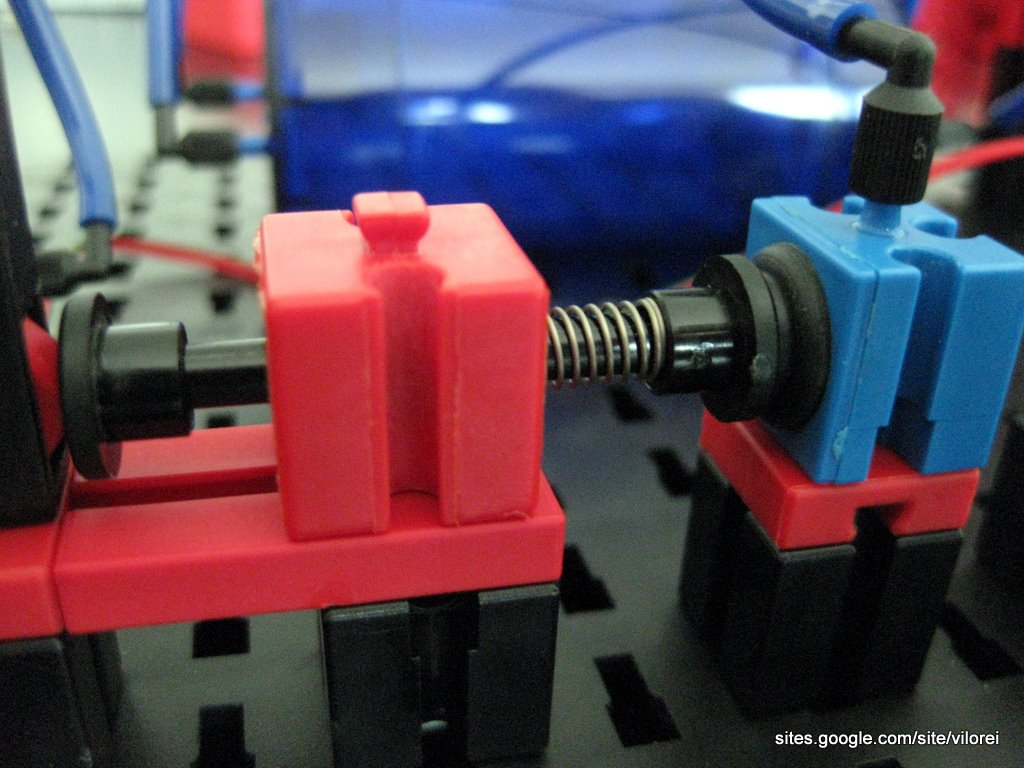

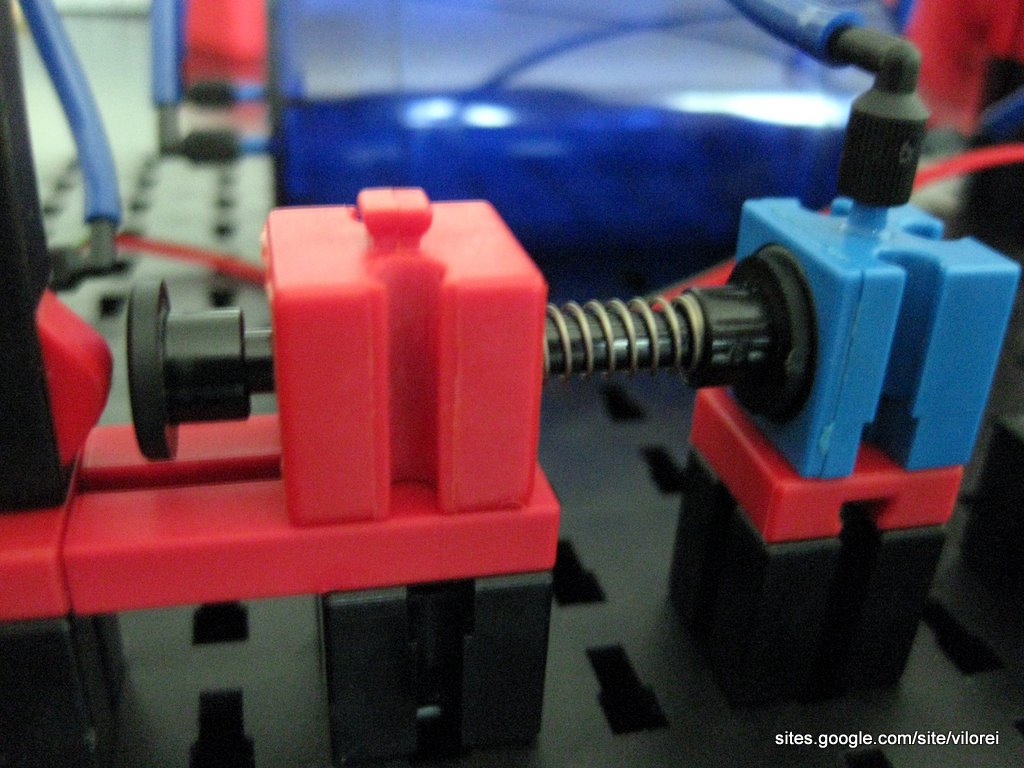

A short black cylinder is recommended because it has less friction. The sensor based solution fits continuous and non-critical usage. However, it's not recommended for vacuum-head, because low air pressure is detected as the very same time the vacuum head is running out of vacuum. Since detection is simultaneous and fails to prevent the object from falling. Below, the same system but with specific elements, as the blue valve reference 36075. |

Left: low pressure ; Right: high pressure.

3. Software Managed Compressor

|

After having looked at mechanical solutions, let's explore what software could offer.

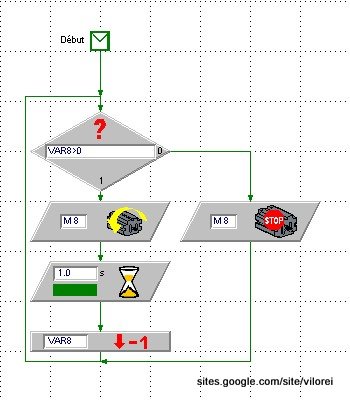

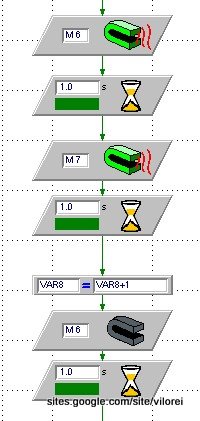

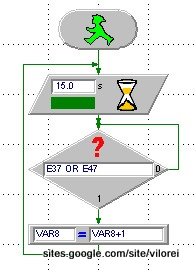

The following diagrams come from LLWin 3. There's no major difference with Robo Pro. First, a sub-routine manages the compressor in a smarter way. The sub-routine checks VAR8, the messenger asking for compressed air. VAR8 represents the number of seconds for compressed air generation. M8 is the compressor motor. |

|

This sub-routine is launched when the model is started.

Let's see two examples: Pressure has to be checked before and be ready for the use.

|

4. Digital Pressure Sensor

Conclusion

|

I've being playing with the three solutions: time, sensor based and software management of the compressor motor.The vacuum head (as in the PneuVac kit) demands constant high pressure.

Problem is, when it is activated, the mechanical safety valve fails to prevent a small drop in pressure, and thus the cylinder carried out by the vaccum head falls. The same happens with the time based solution. Actually, the needs for vacuum head should be anticipated: only a software managed control could profide such a feature. This solution is used on the Magasin 9 model. However, for models involving compressed air and not vacuum, the mechanical sensor provides a perfect answer. It also frees one motor from the time controlled solution and one output port from the software managed solution. |