Compressed Air And Vacuum For Z-Axis

|

One of the major challenges of the Magasin series was the management of the compressed air. It relied on a ft compressor and vacuum was obtained through a tricky pneumatic system. Direct consequence was, any single variation in the use of compressed air may result on the depletion of vacuum, and thus the fall of the cylinder.

Even elaborate management of the compressor by software wasn't fully satisfactory. It became clear that the standard ft compressor powered by a mini-motor (reference 31077) wasn't designed for such intensive an use. Just remember the first ft air compressors were either a professional device (reference 30864) or powered by hand (reference 30865)! So I went for a pump, actually two pumps: one for compressed air, another for vacuum. Here are shown the results. The technical details will be provided later on. |

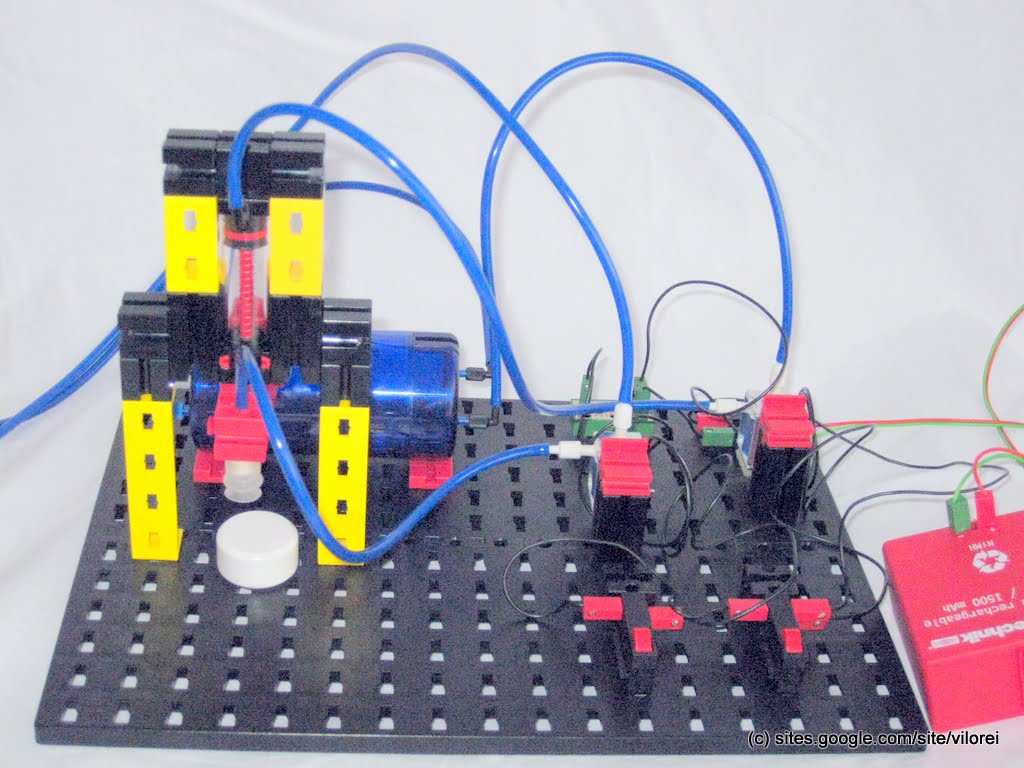

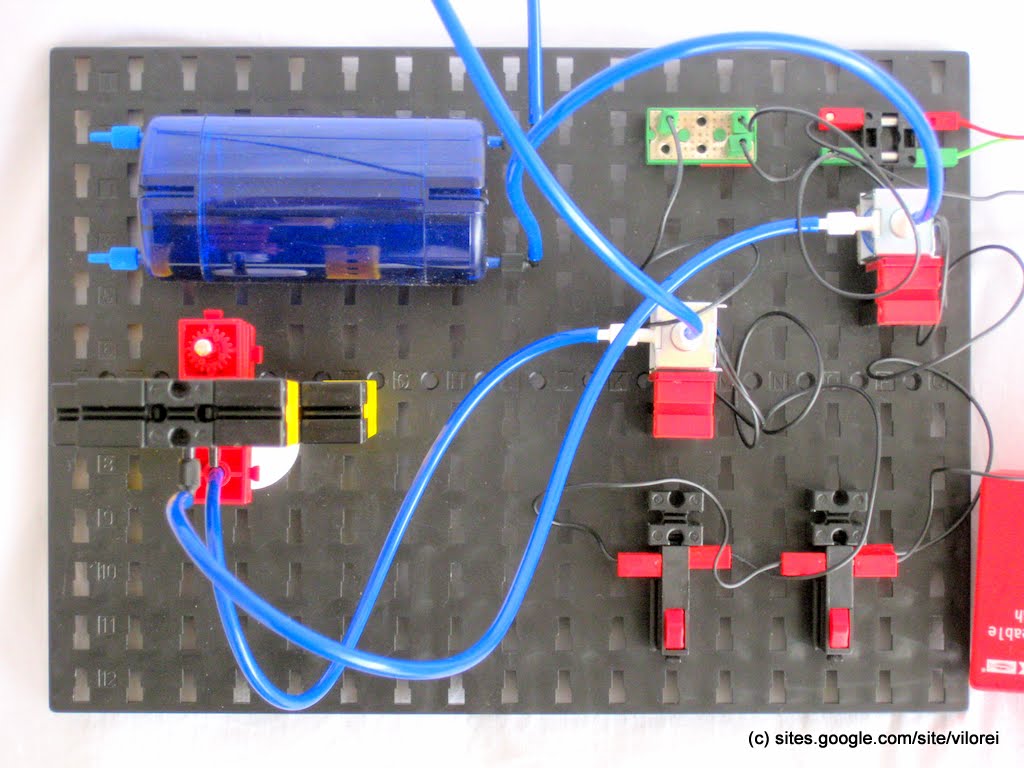

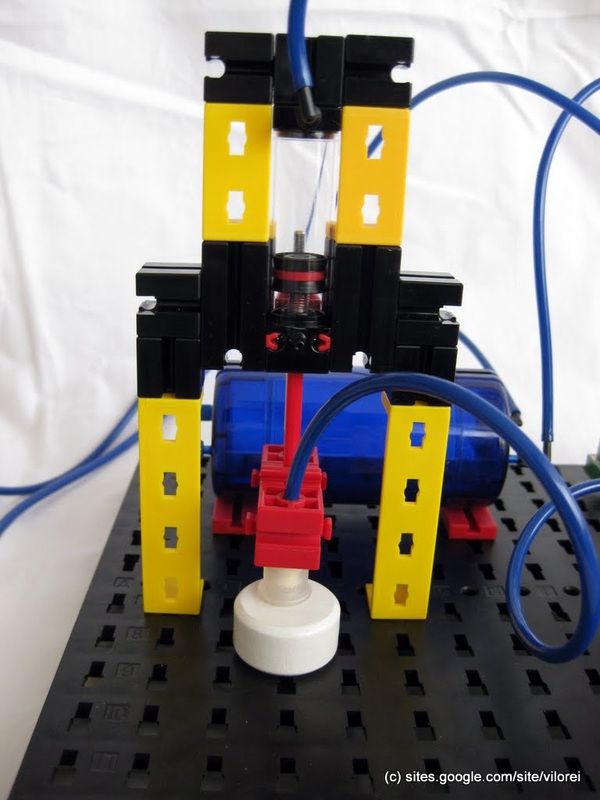

General View

|

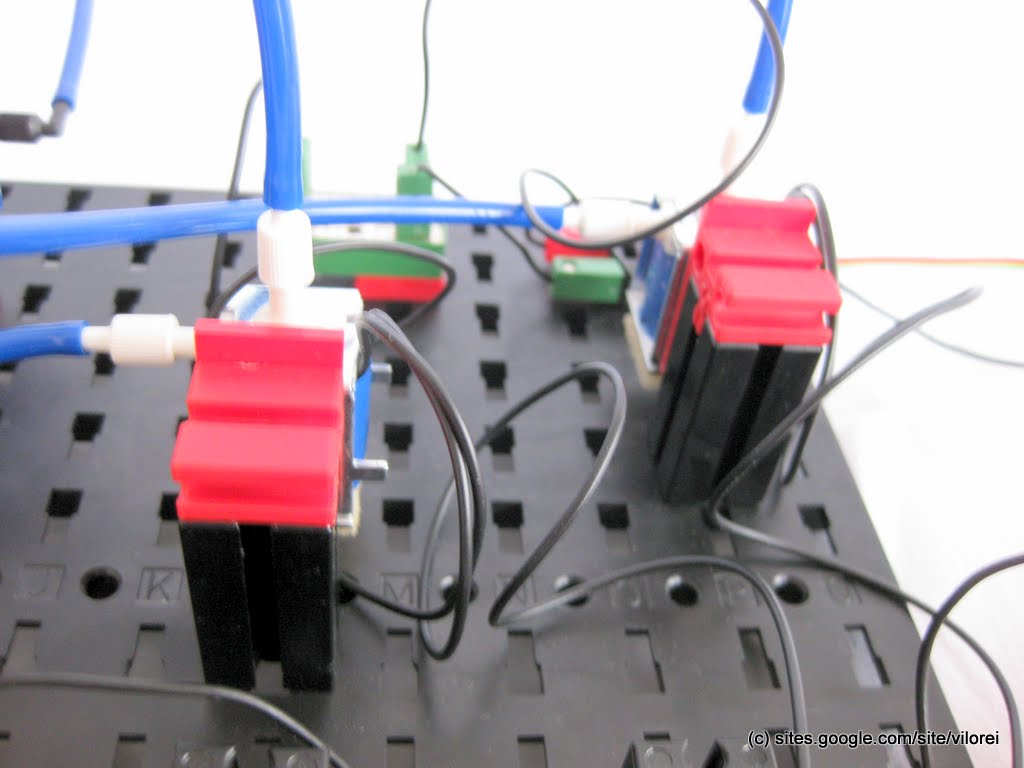

The Z-axis is built with two solenoids and two switches.

Compressed air requires a tank while vacuum could be connected directly. |

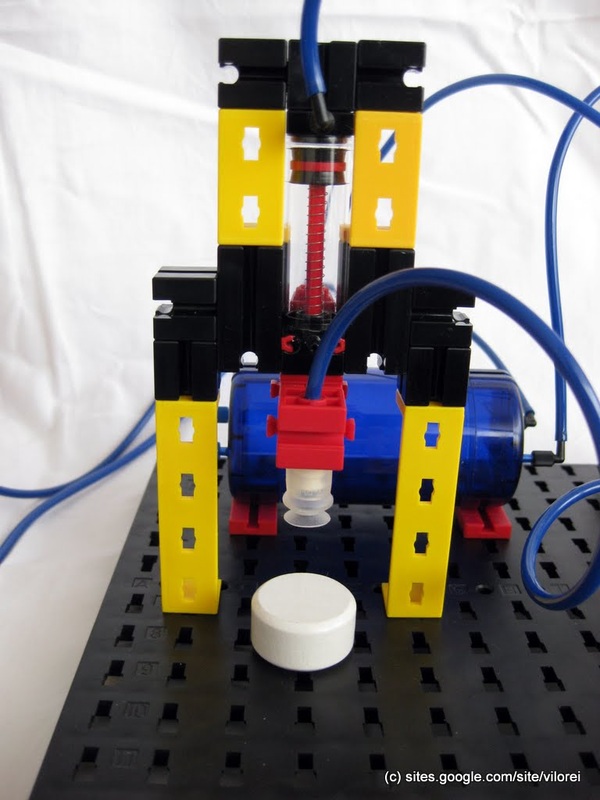

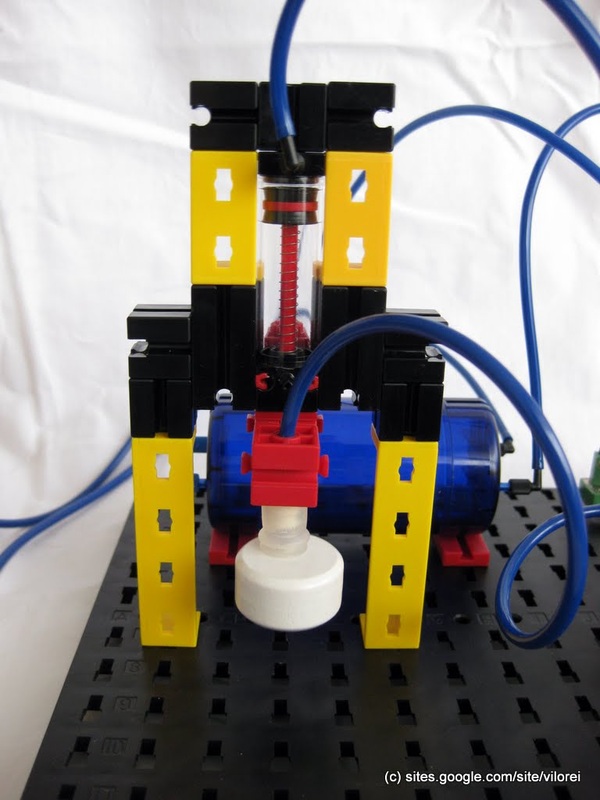

In Action: Pictures

|

From left to right: initial position, down and vacuum, up and vacuum.

|