Pictures

|

Please have first a look at the very nice portofolio of pictures taken by Dinomania01 during the ft-convention.

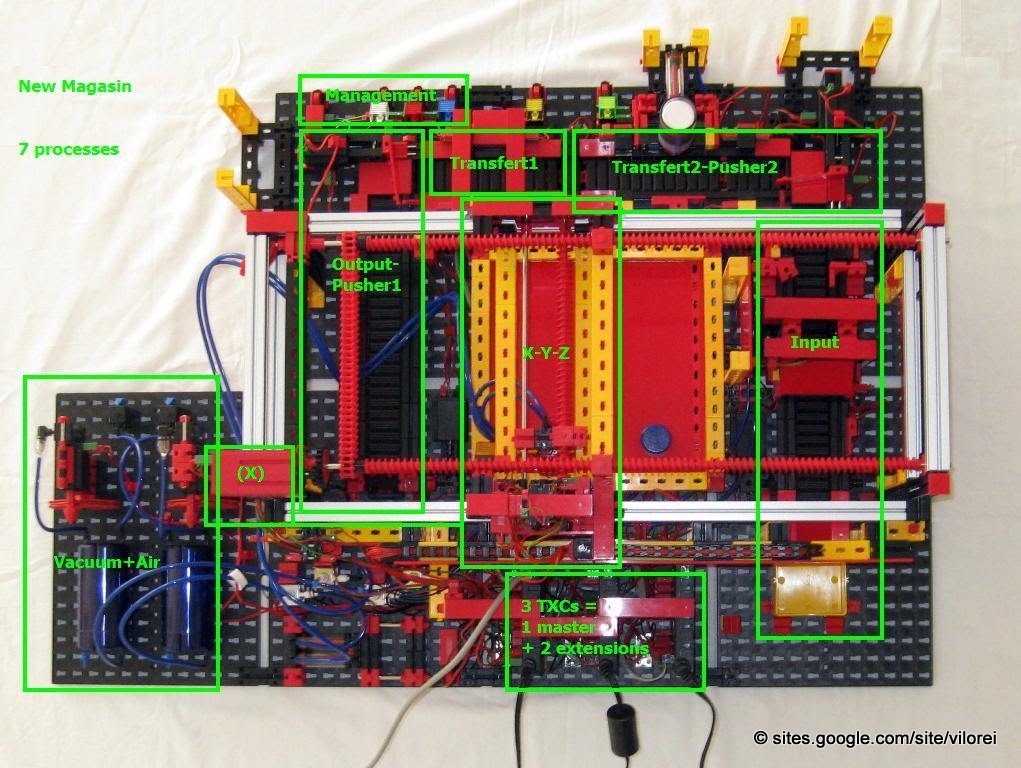

Here are the pictures filed by main processes. |

General ViewsThe general view gives an idea of the size of the model.

Aluminium bars provide great stability. The 3 TX controllers, one master and two extensions. Two compressors, one for compressed air and another for vacuum, with the classic mechanism. |

|

InputThe cylinders are on a silo.

From the silo to the colour reader, through the pusher for a 90° turn. Clockwise, from top: silo, input, pusher, door, colour reader and picking area. The door protects the colour reader from ambient lighting. The colour reader requires perfect positioning, obtained by a light barrier (lamp and phototransistor). The colour reader features a white LED for better results. |

|

OutputClockwise, from top: the deposit area, the pusher, the delivery area.

Detail of the pusher and the delivery area. |

|

X Y Z AxisThe moving desk is the most complex part of the New Magasin model.

It features three axis X, Y and Z plus a vacuum head.

In order to ensure a smooth translation, a snake (reference) is used for the electric cables, as well as and specific fixings for the compressed air and the vacuum. |

|

The Front LineThe front line is just in front of the user. Lamps provides information and buttons receive orders.

Three buttons for colour request. The lamps above are switched on when the corresponding colour is available. |

|

Access for MaintenanceAs always in industry, safety comes first!

How to bring at the same time high security level and easy access for maintenance? Here's how.

|

|