Pressure Sensor

|

I selected a pressure sensor from Freescale Semiconductor wide range. I picked up one with the following specifications: integrated, absolute measure, 0 to 250 kPa.

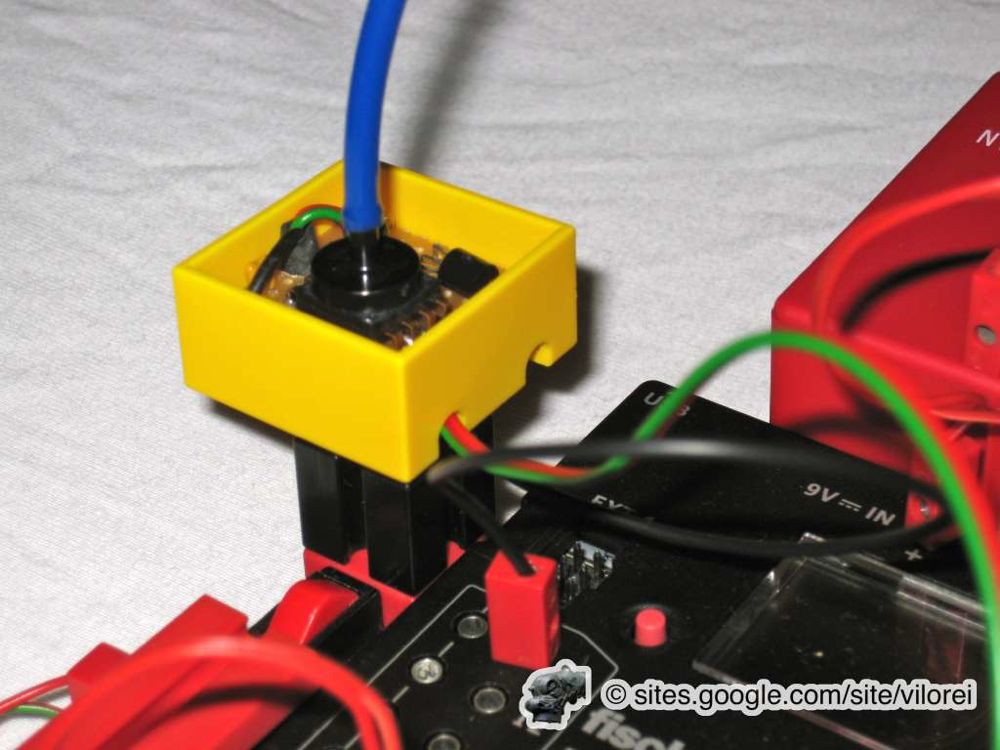

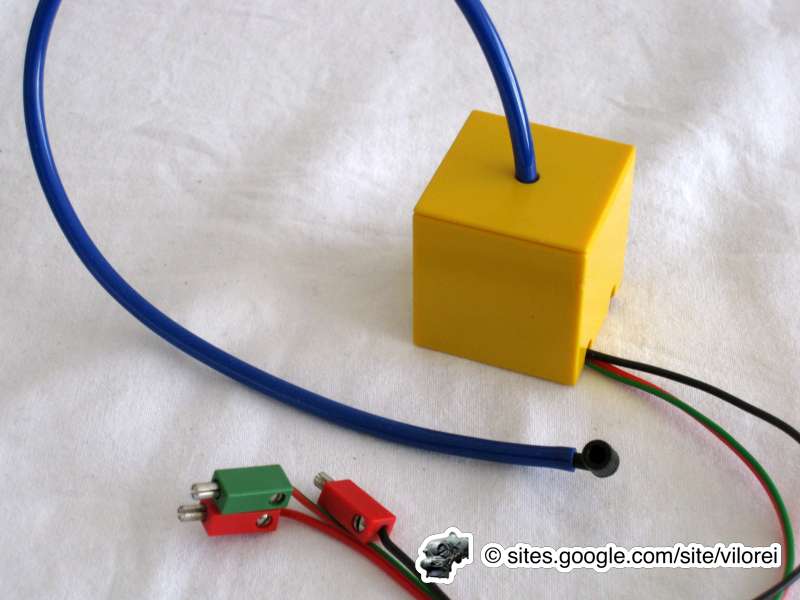

It comes in various form-factors, either small outline / surface mount package or unibody package, with or without a nose. The manufacturer provides an excellent application note Understanding Pressure and Pressure Measurement. The sensor provides a voltage linear to the pressure measured. So implementation is rather easy. After extensive testing with the Arduino board, I went into packing the sensor into a fischertechnik block so I could use it with my industrial models. |

Pressure Sensor Tests

|

I carried out some tests with the pressure sensor on an Arduino board.

How many measures per second? What is the reactivity? The sensor is powered by a fischertechnik battery. Signal is sent to A0 analog input. When used, SD card is connected to TX → 1 pin. I guess the hardware has a consequence on the measures:

Measures rate and reactivity are good enough for my fischertechnik industrial models! |

|

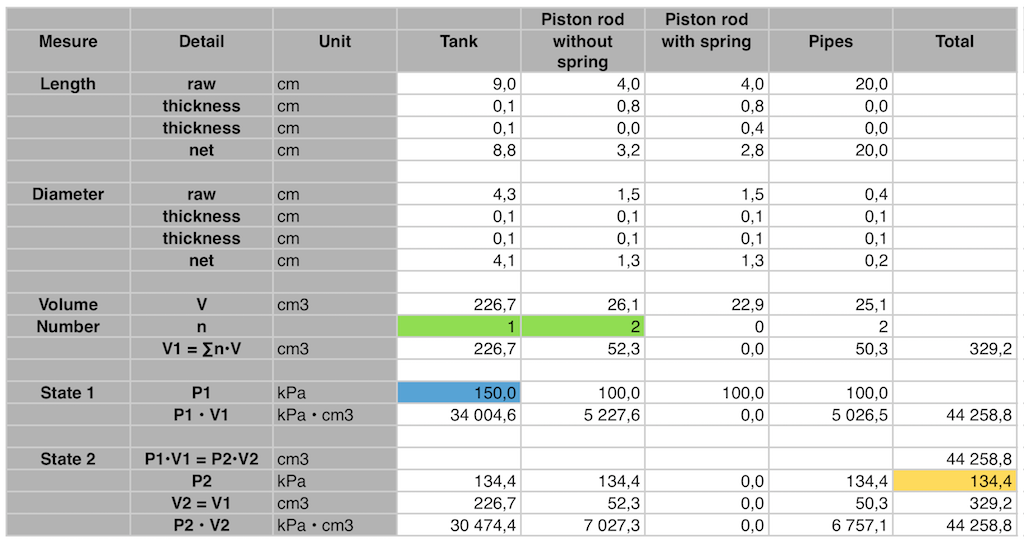

Pressure Sensor Mathematical Model

PV = nRT I considered R and T as constants and took 1 atm close to 100 kPa. Actually, 1 atm = 101,33 kPa instead of 1 atm ≈ 100 kPA.

I measured the volumes of the tank and the piston rods, with and without spring. I conducted two series of measures:

As always, the model and the measures are provided below. It's always nice to see that Nature obeys physical laws! |

Results and Interpretation

|

The findings are:

Now, how to build a smart pressure management? |

Downloads

|

Please find the RoboPro project and the Excel sheets discussed in this article.

|

| ||||||||||||||||||