Management Panel

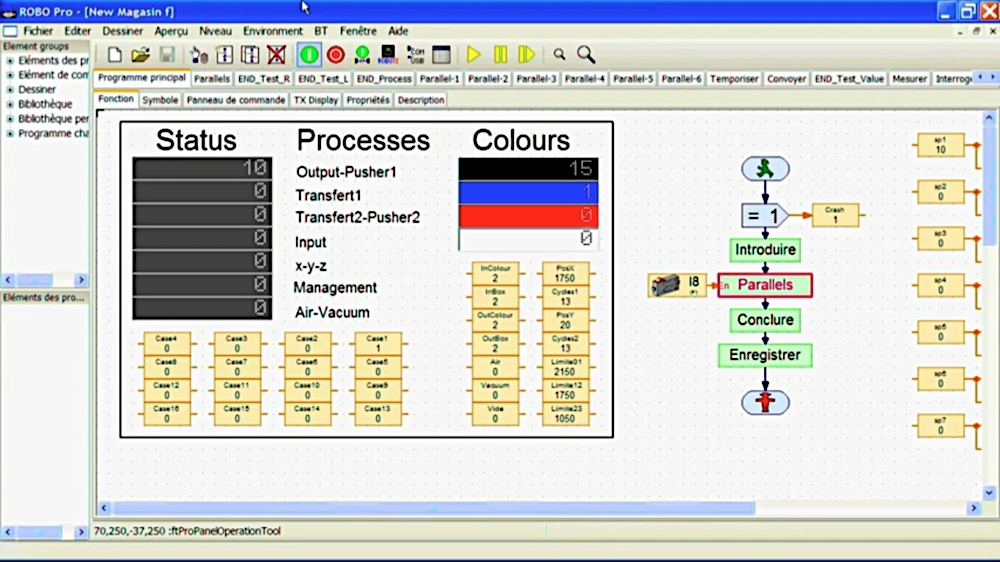

1. Standard

|

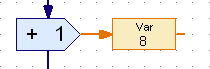

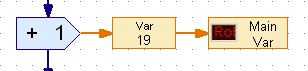

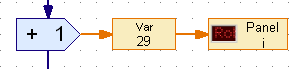

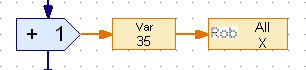

The standard uses the Var boxes and the Interface Test window to show values, inputs / sensors and outputs / actuators.

This option only works on debugging on-line mode. This option is great for debugging because it operates on the working area where the algorithm is, but the Var boxes could be difficult to read. |

2. On the Working Area

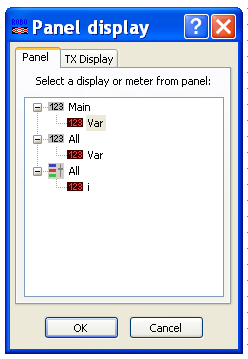

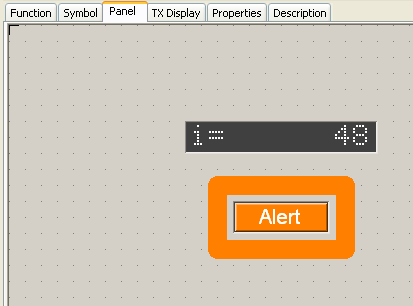

3. On the Command Panel

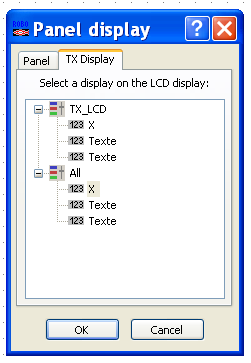

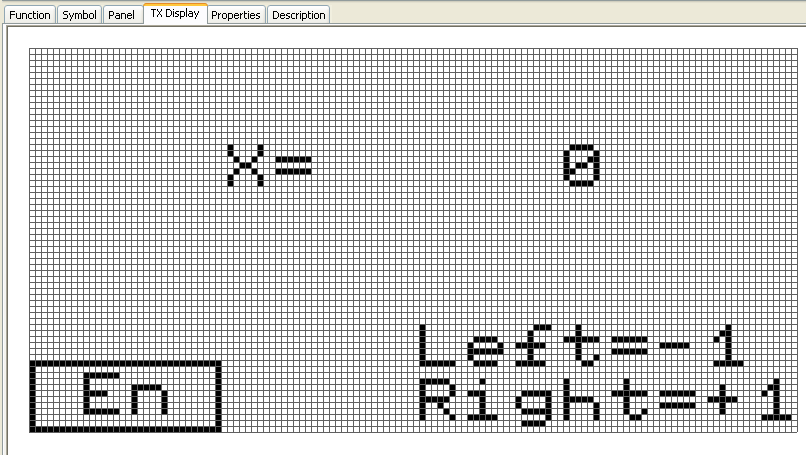

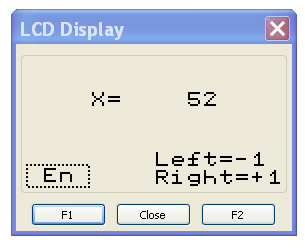

4. On the Robo TX LCD Screen

5. On an External I²C Display

|

This option requires an external display and the use of the I²C driver suited for it.

Learn more at I²C LCD screen 4 lines of 20 characters LCD03. Right, the I²C LCD panel for the electro-pneumatic flipper. |

Download

|

Download the driver with an example for RoboPro.

This file is under the Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License. |

| ||||||