Automation Robots Set — High Bay Storage Rack Fixes

|

The high bay storage rack from the Robo TX Automation Robots set is an amazing piece of engineering.

However, it requires a precision of less than 1 mm, close to fischertechnik system limits. Some axis are too tight, some parts require manual adjustment. Here are the modifications I brought to the initial design in order to improve the reliability of the model. Please refer to the manual for the parts list corresponding to the mentioned steps. |

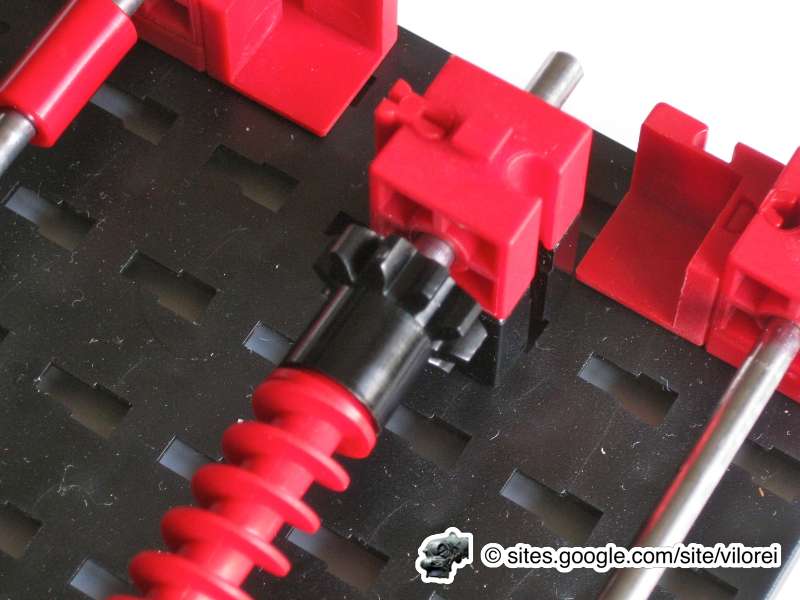

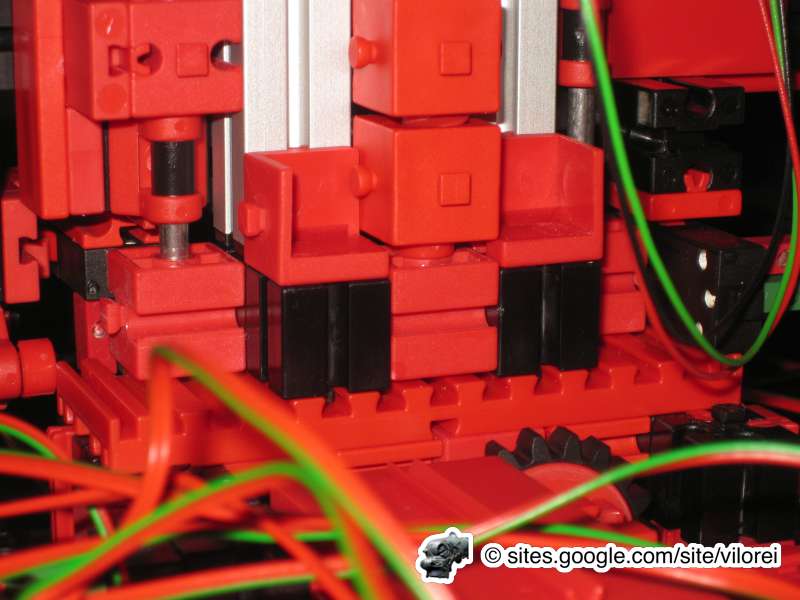

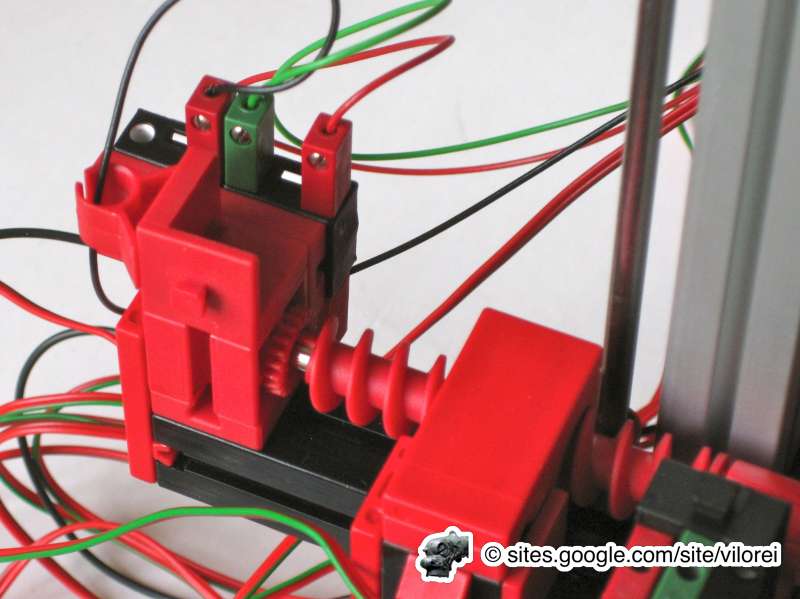

Step 4

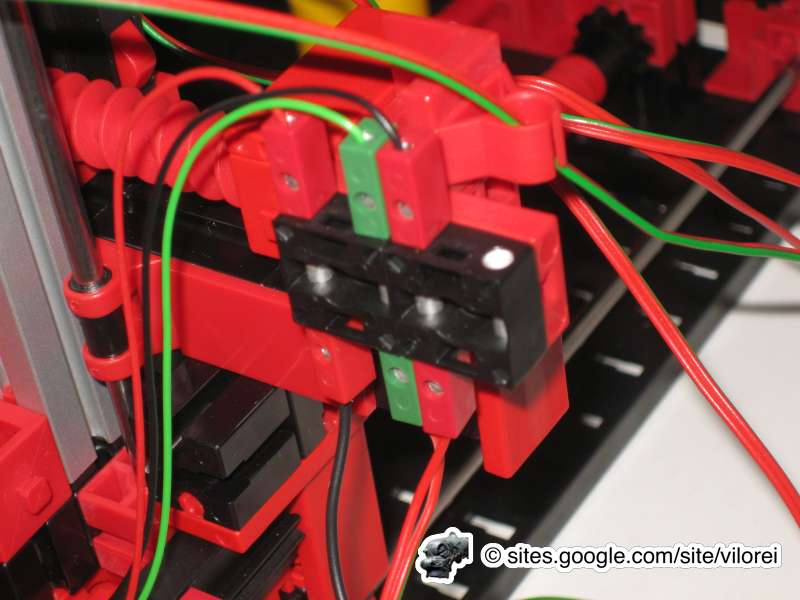

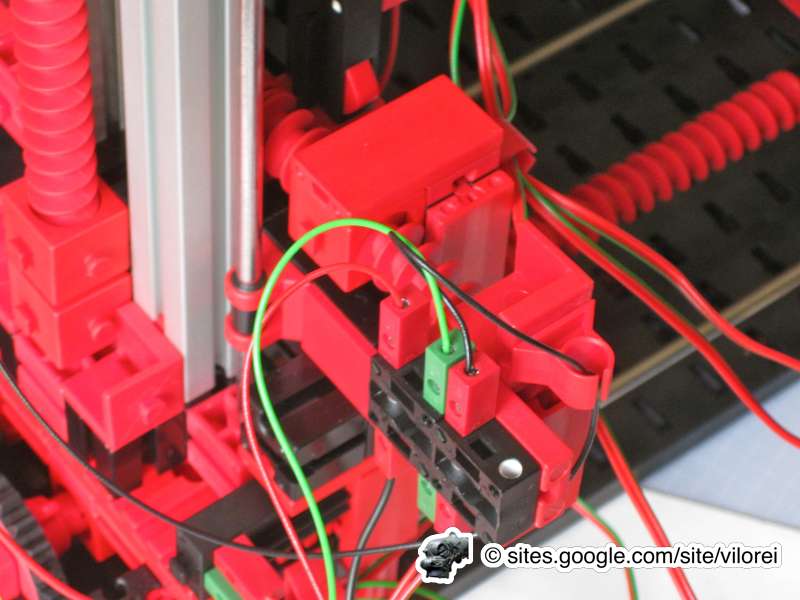

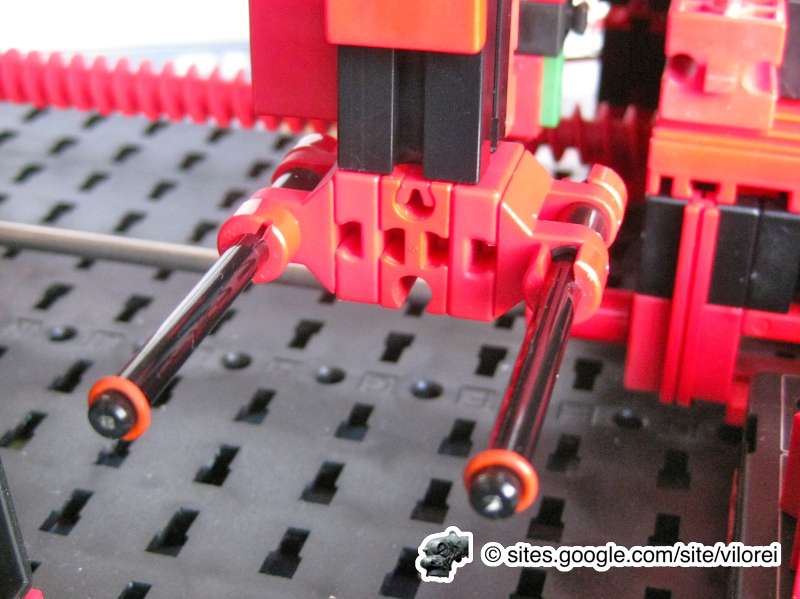

Step 8

Step 20

Step 22

Step 23

|