Another Sensor

|

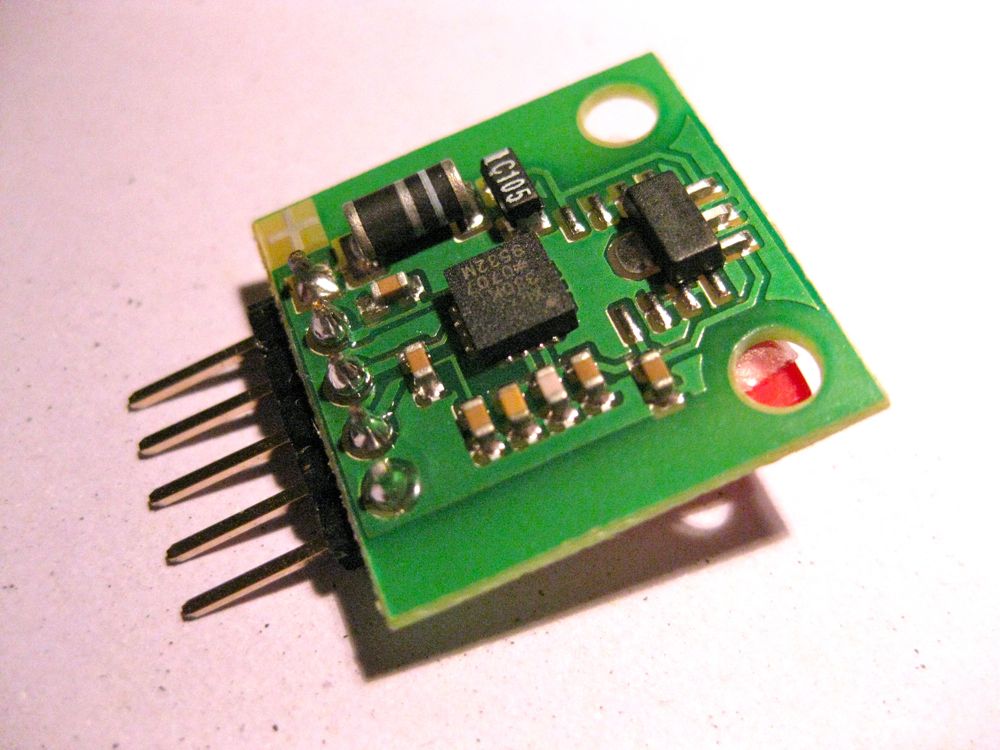

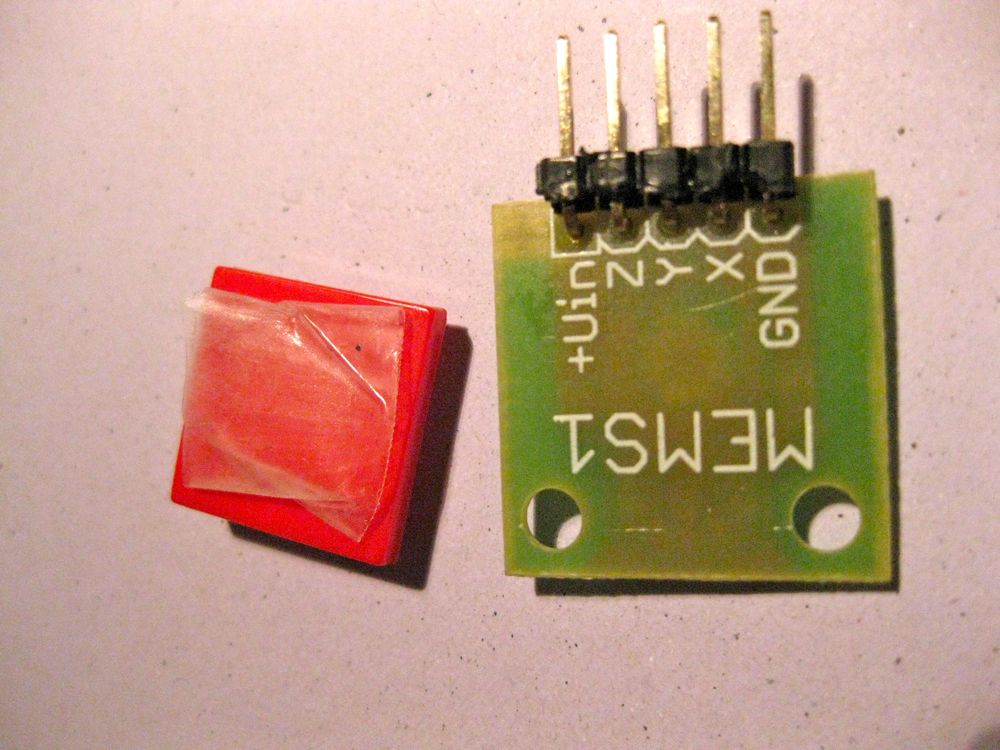

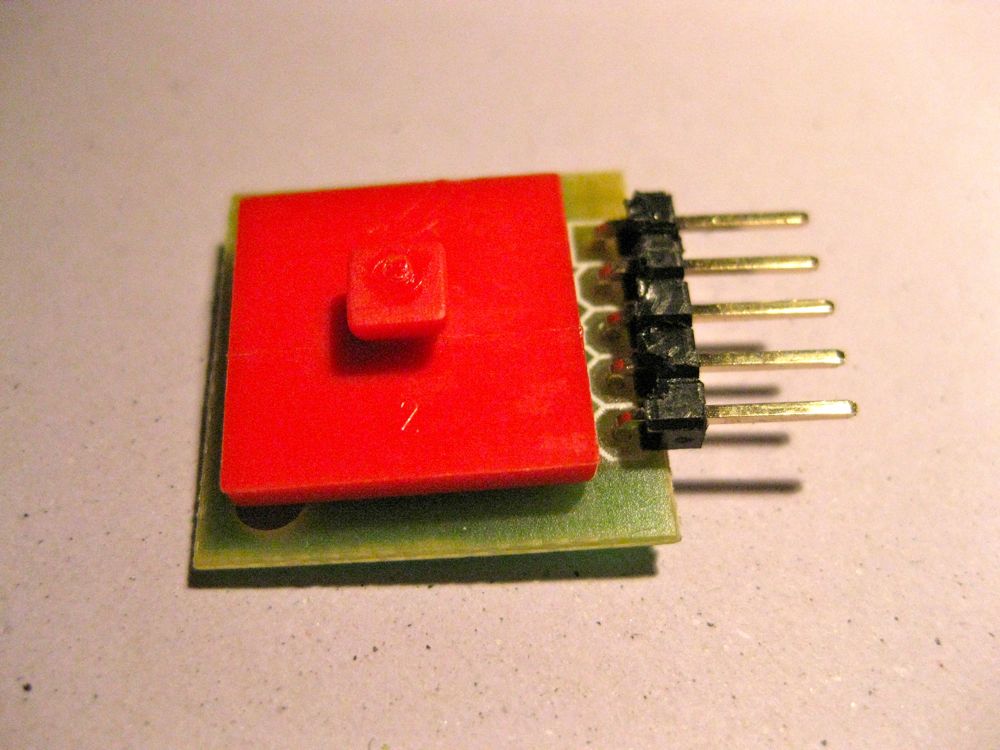

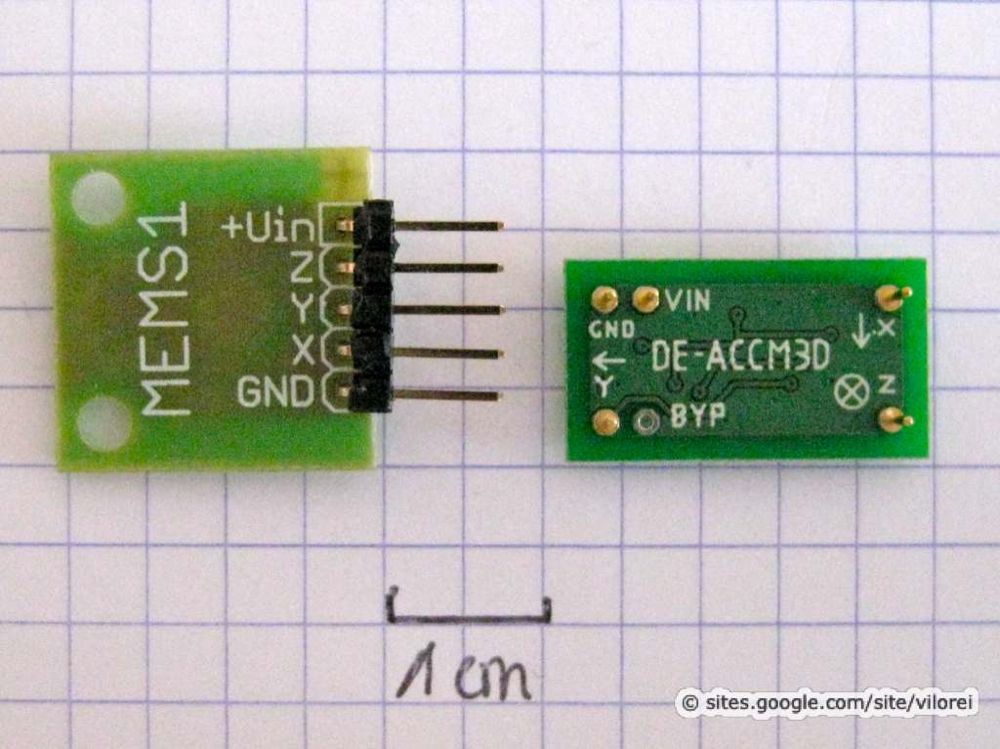

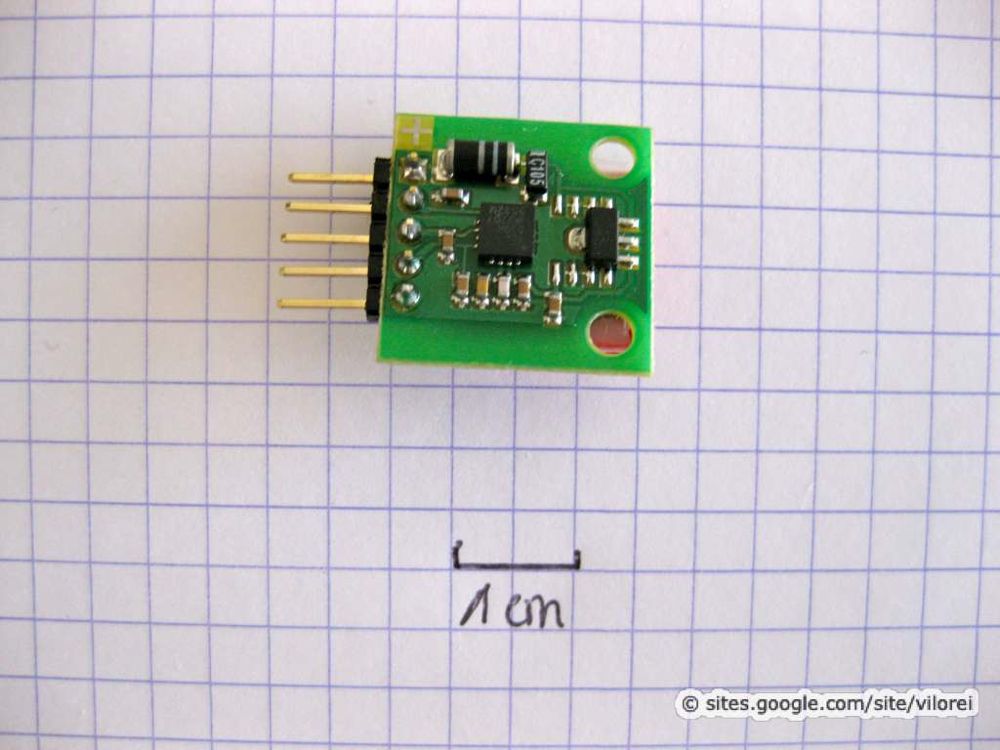

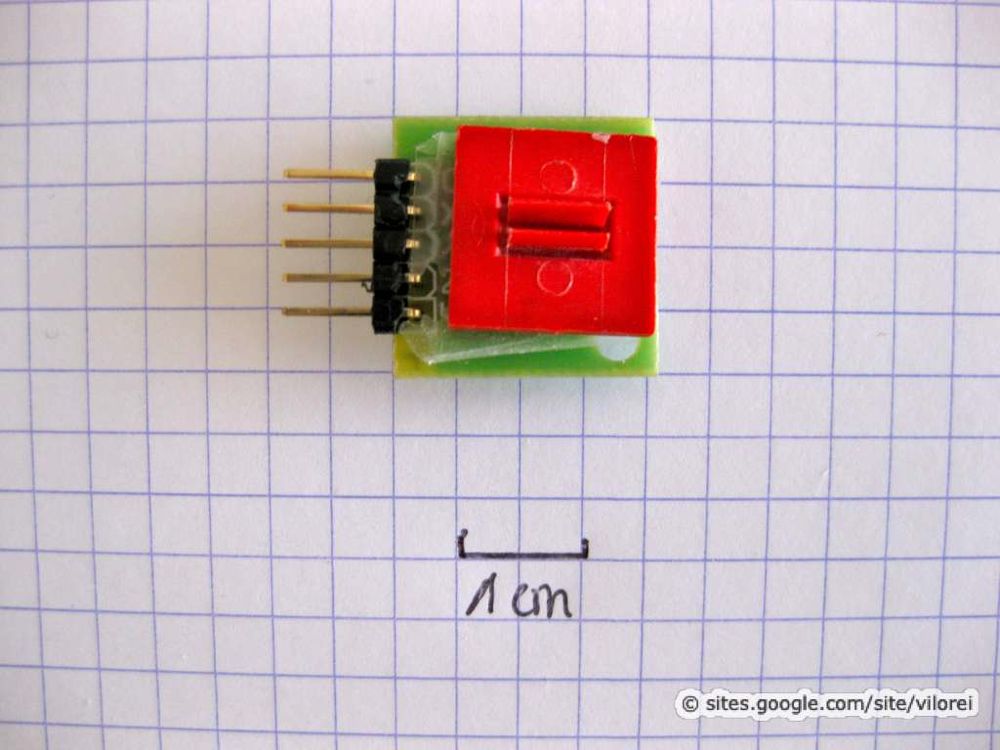

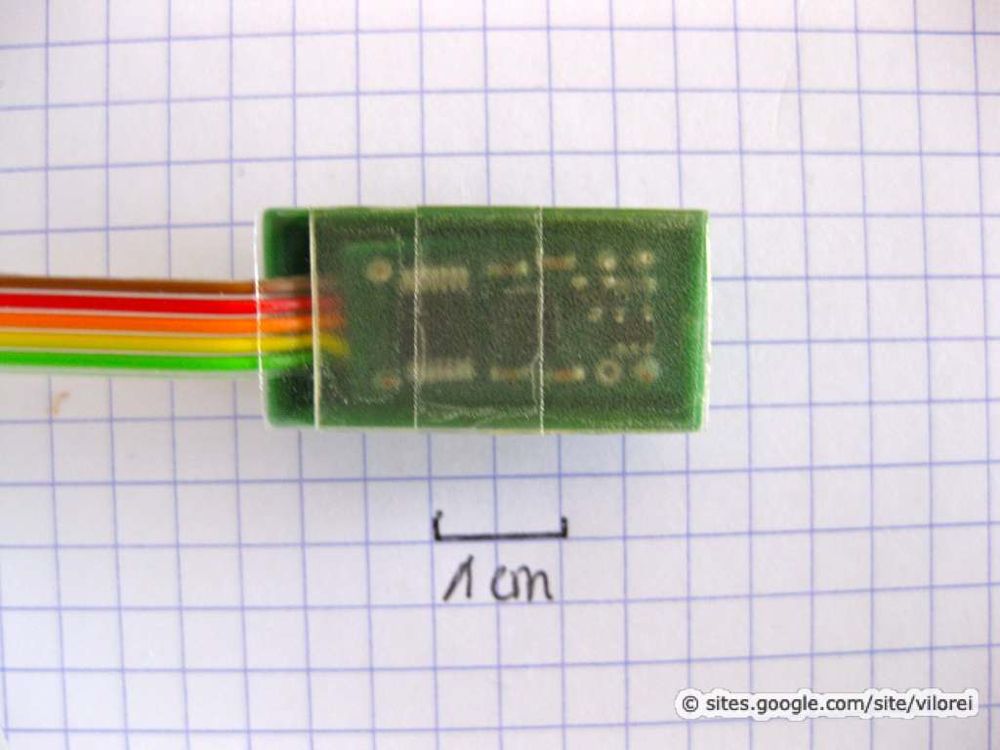

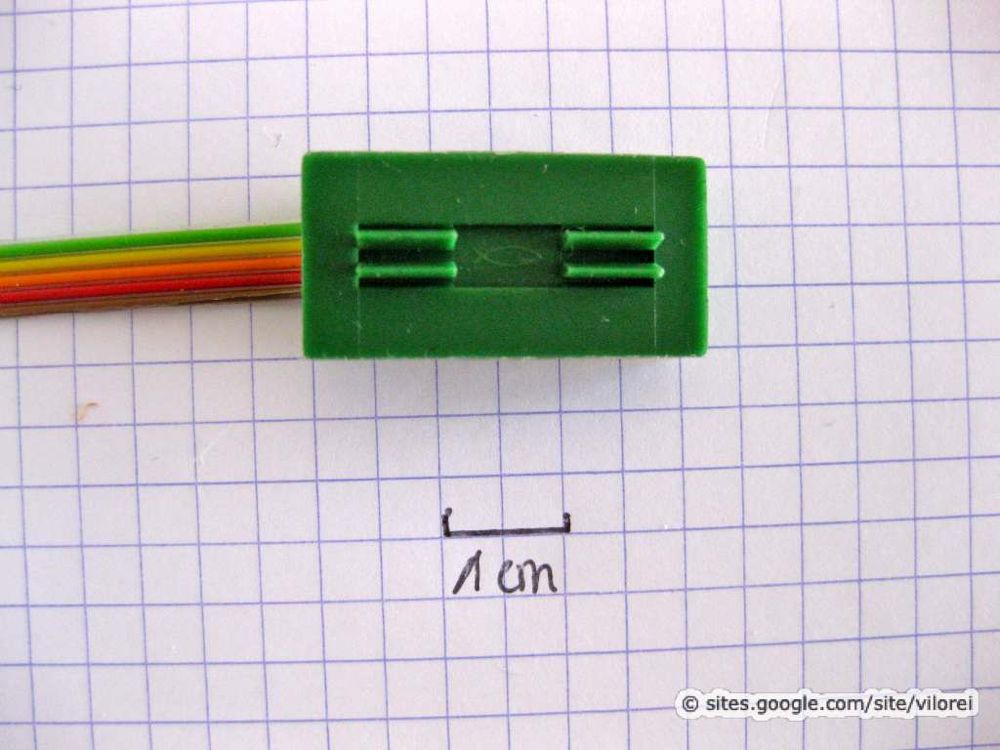

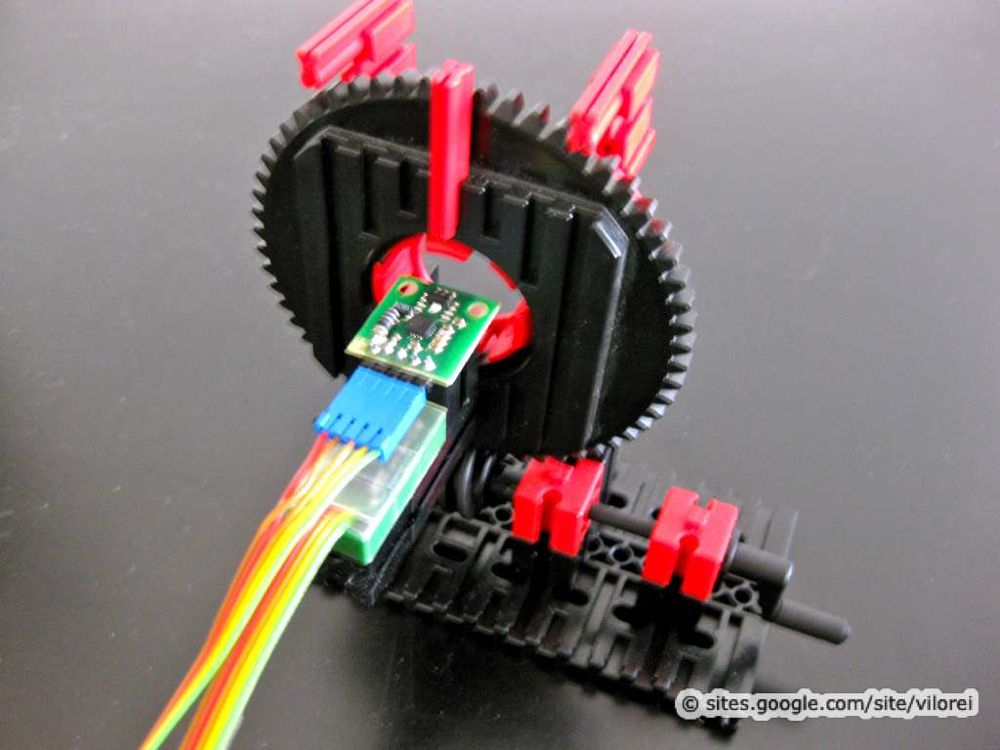

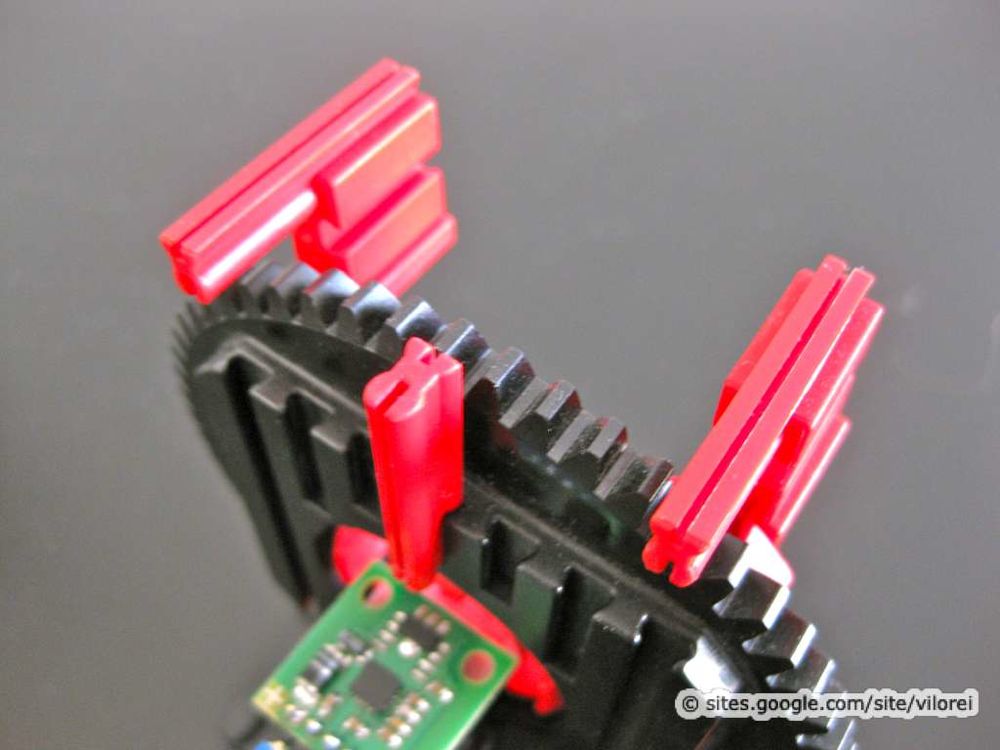

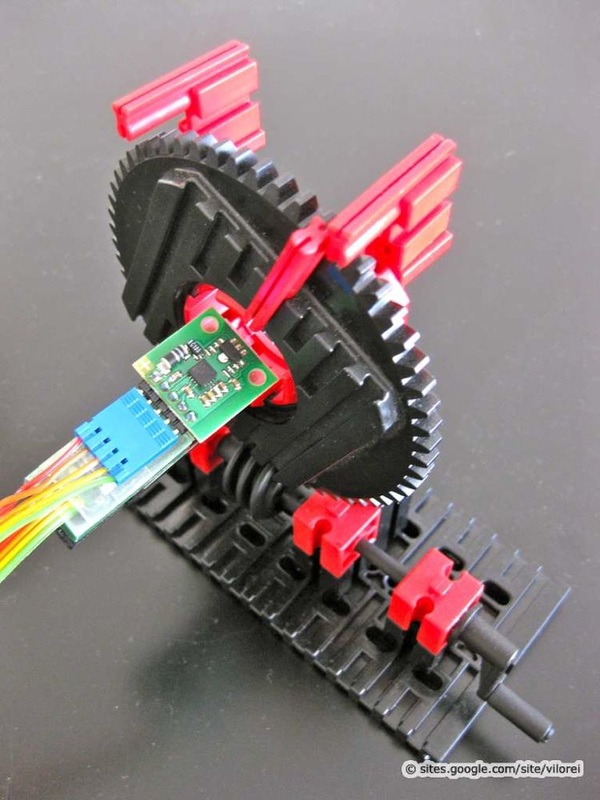

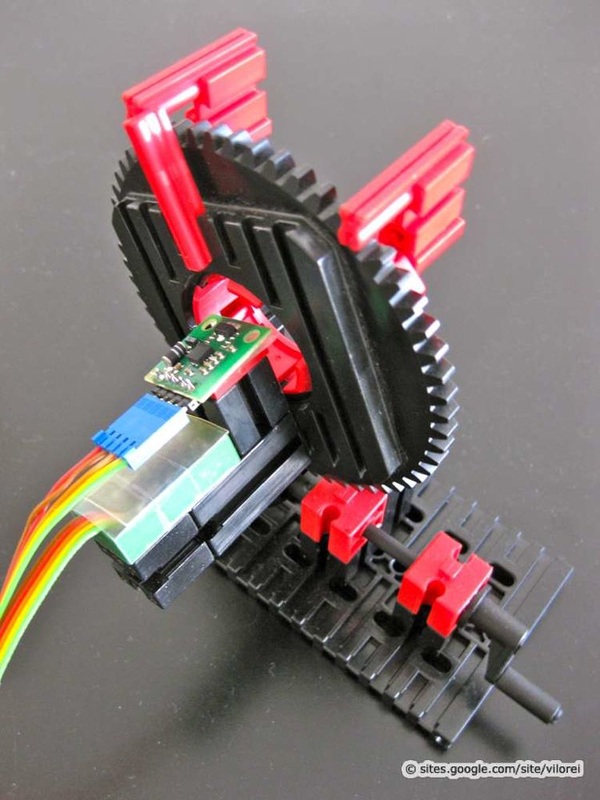

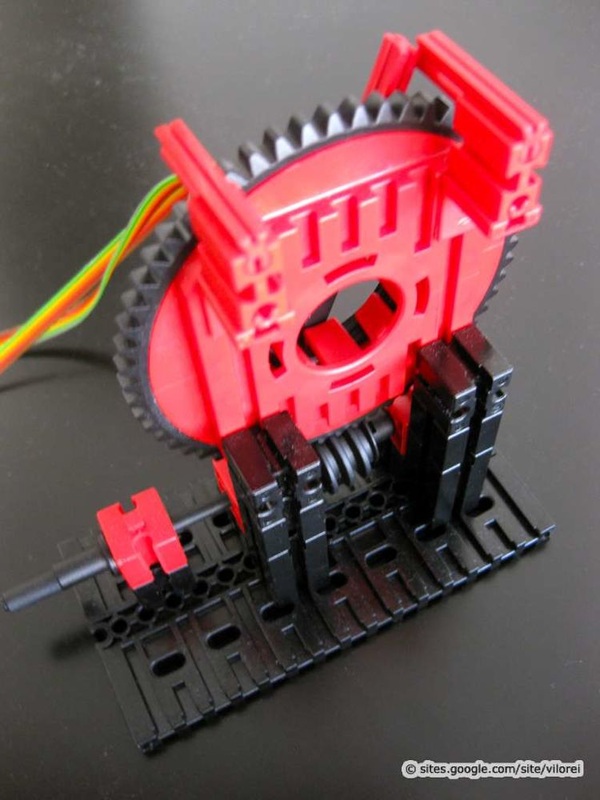

Here's the sensor from Neuhold mentioned on the ft:c forum. The breakboard is supplied without pins, so some soldering is required.

|

|

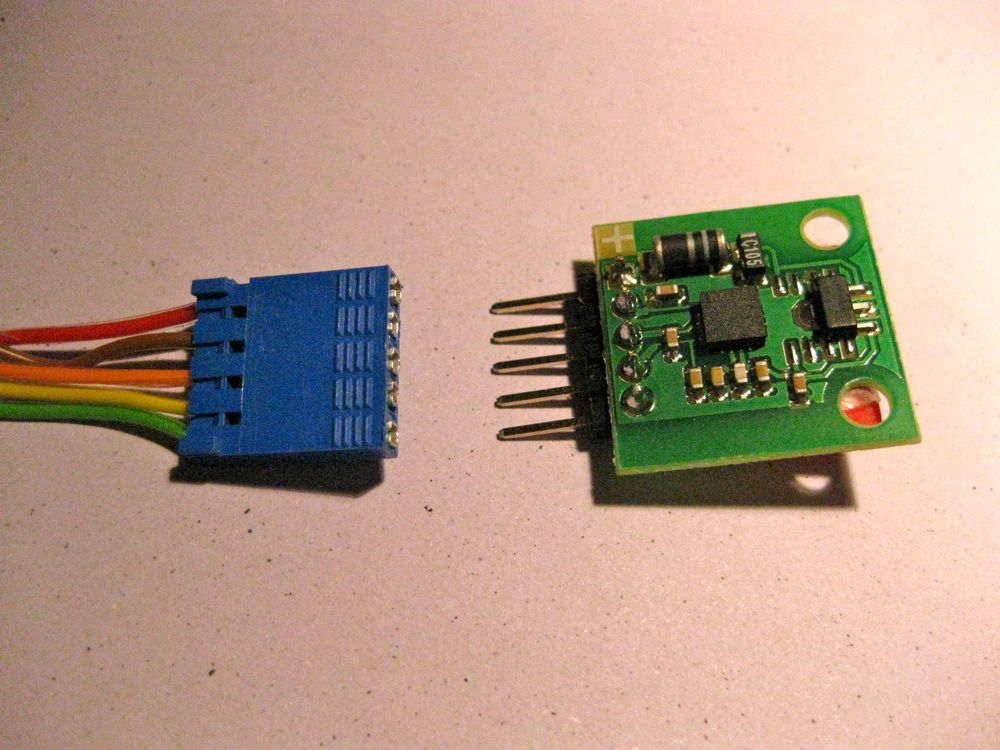

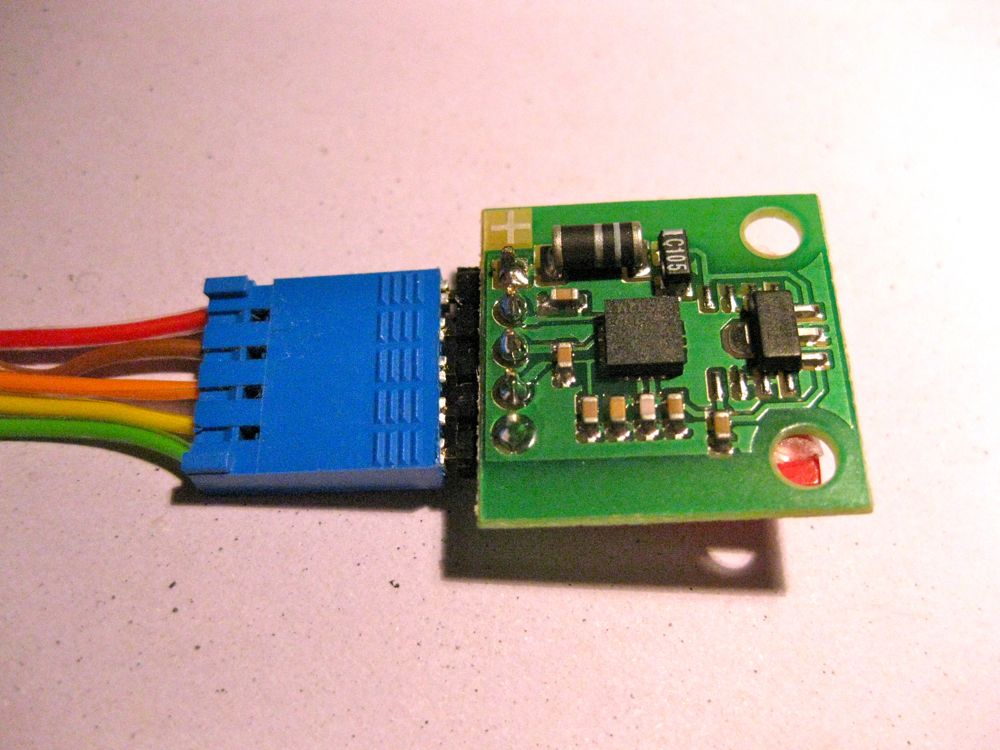

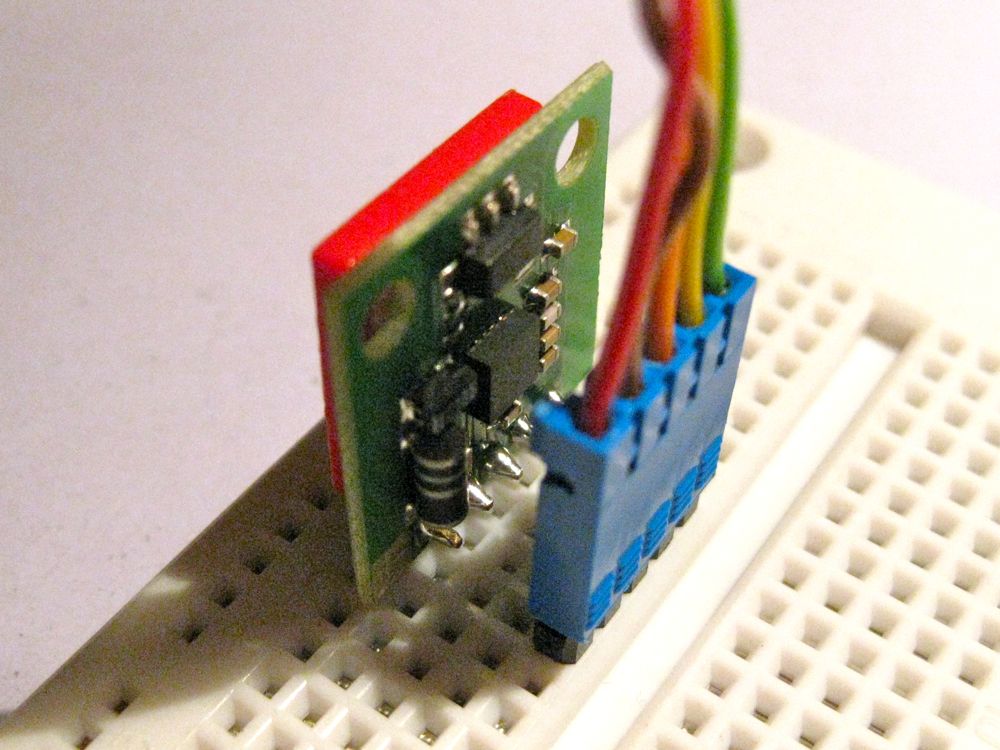

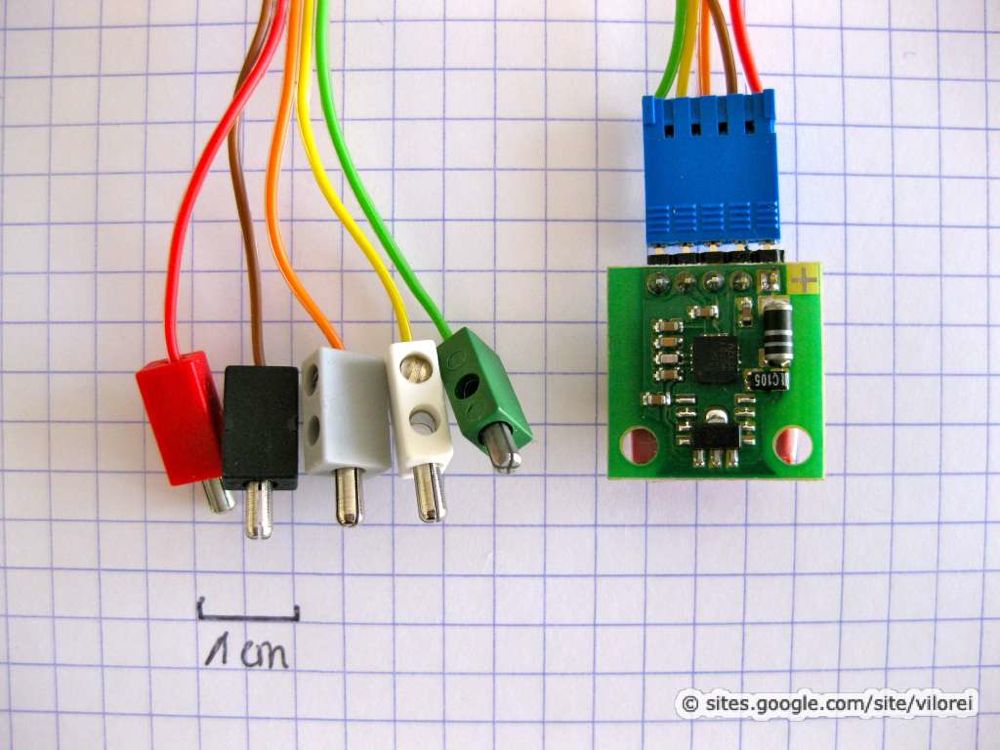

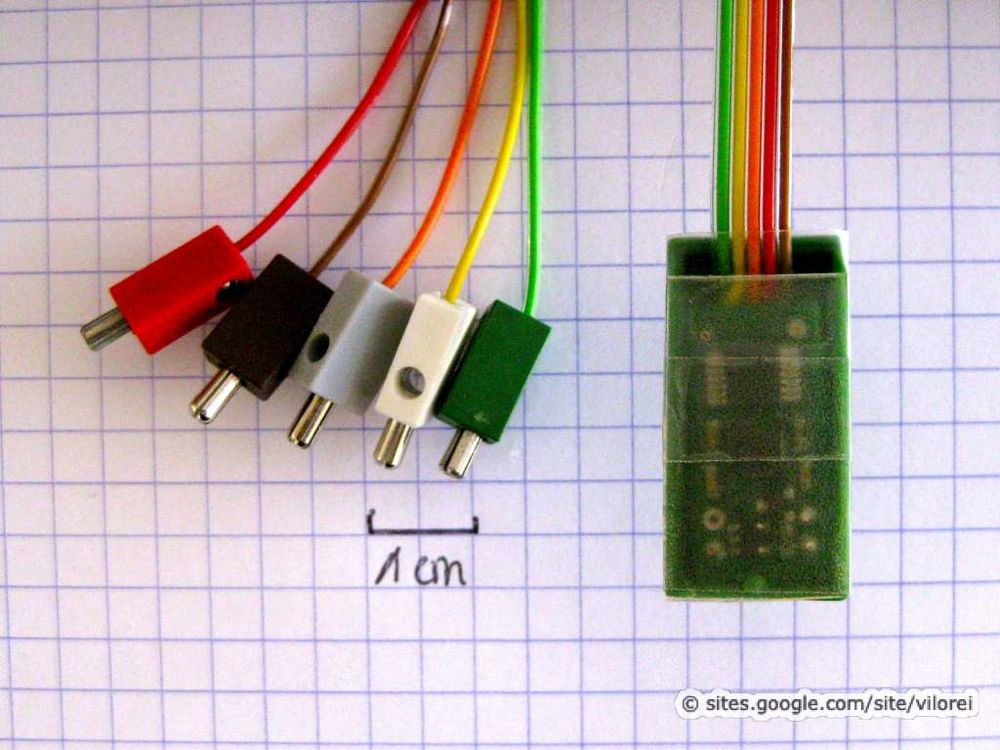

I soldered standard 0,1" HE14 headers and used a nice blue Berg connector (reference). The flat cable ends with 5 fischertechnik plugs.

|

Comparison Between Sensor Implementations

|

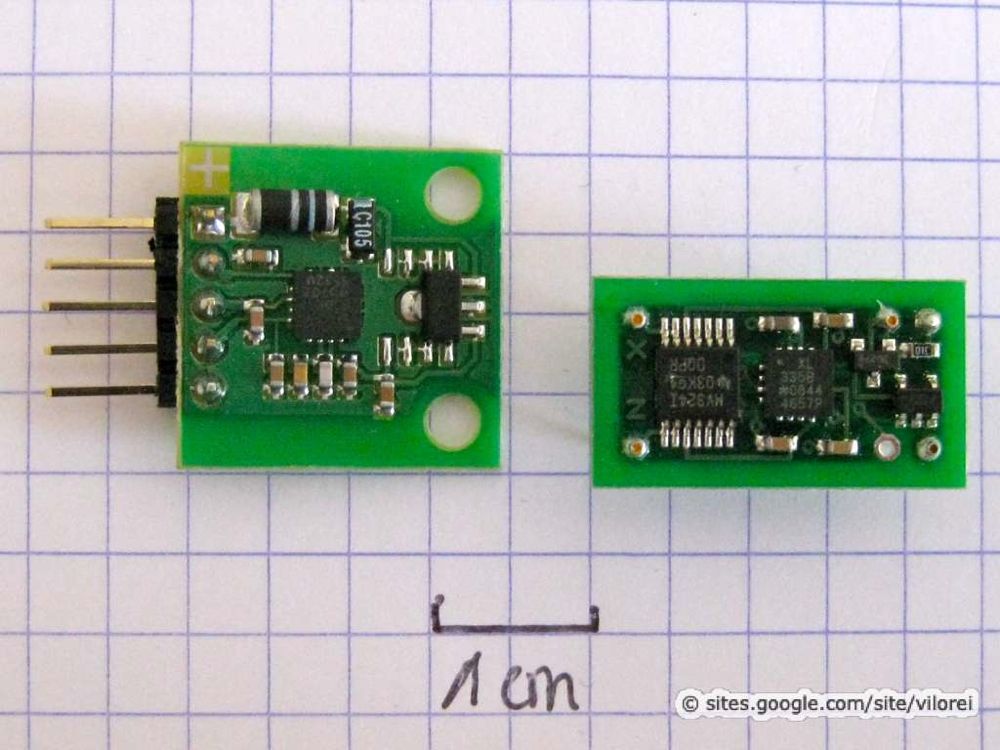

Apart from the voltage regulator and the accelerometer, the Dimension Engineering board includes a third IC, an operational amplifier.

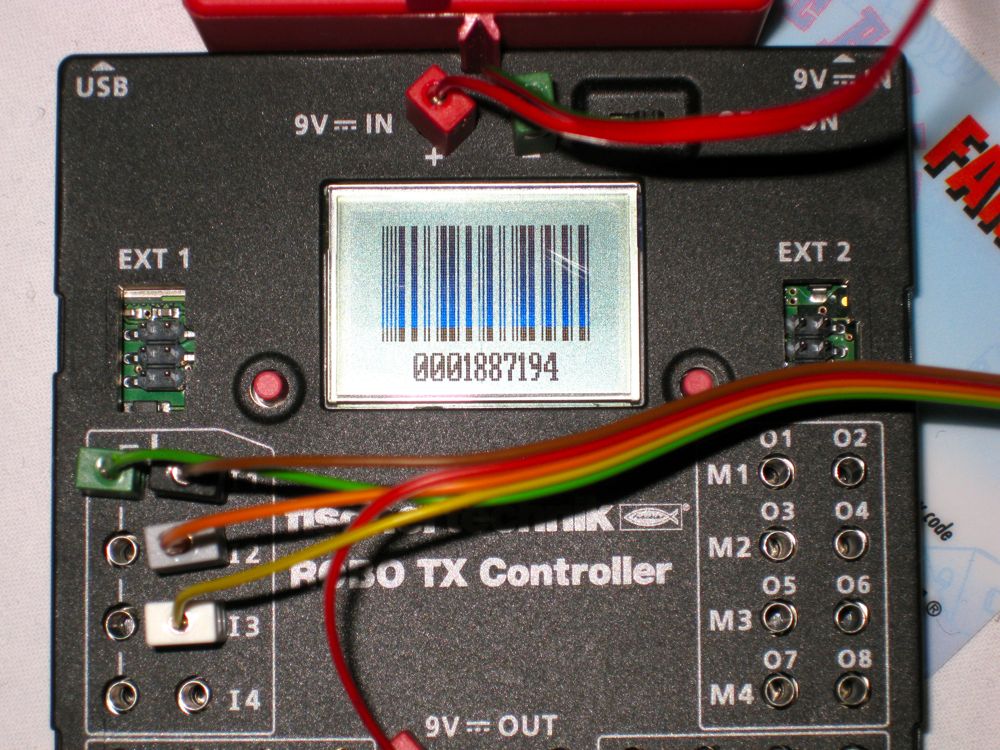

This avoid the nasty bar-code from appearing on the TX controller screen during boot-up. When the Neuhold accelerometer is connected to the TX controller, the following screen may pop-up when turning the power on. Here's the detailed explanation I received: This bar code screen shows the serial number of the ROBO TX Controller. This screen shows up if the input I1 detects a resistance of 13 kOhm (+/- 1kOhm) during the start of the controller. This is far out of the specified measurement range (0 - 5kOhm). So normally this case shouldn't happen if you connect standard ft-sensors to the input I1. By pressing one of the controller buttons you can return to the normal operation mode. |

|

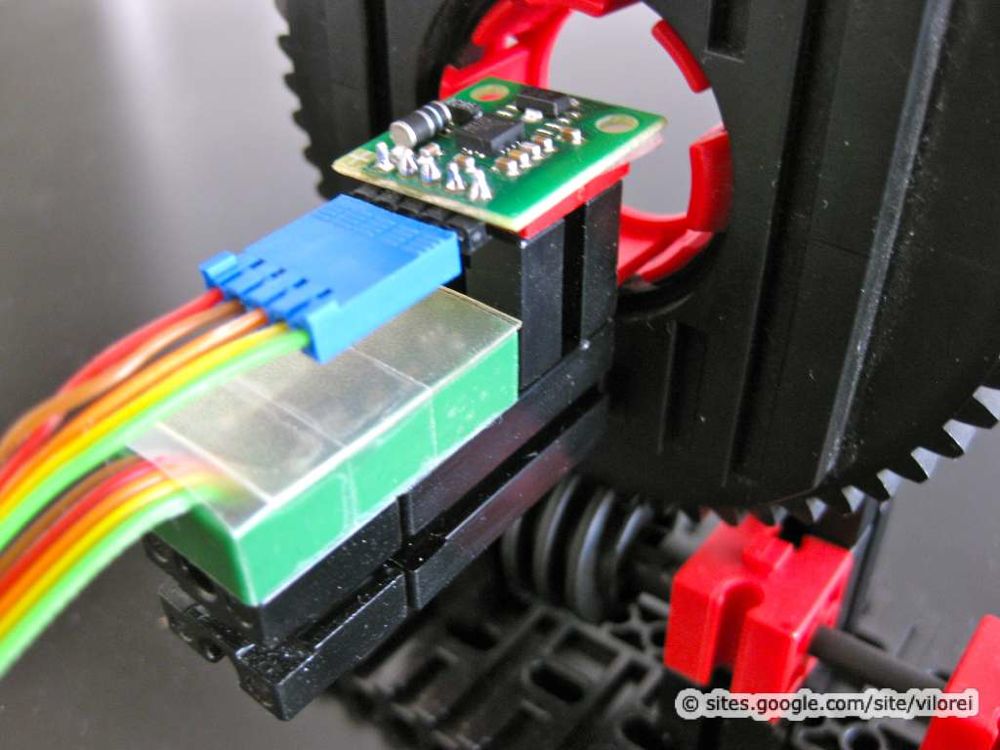

How to implement those boards into a fischertechnik model?

|

Neuhold Implementation

Dimension Engineering Implementation

Implementations Comparison Protocol

|

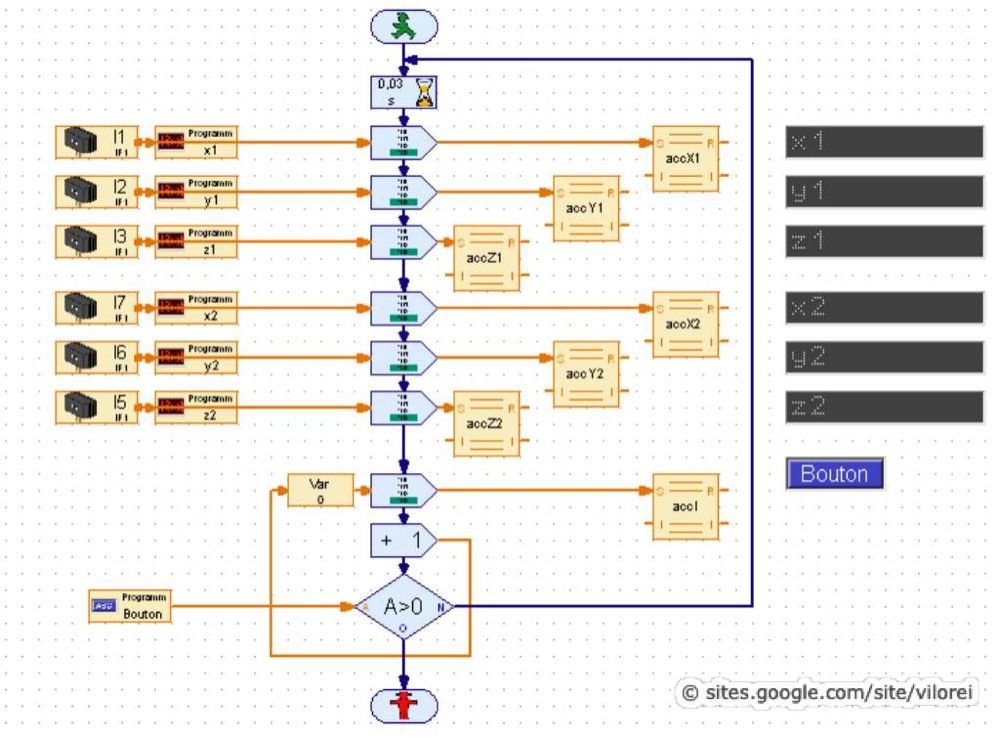

The Robo Pro project is fairly classic, based on the CSV output file.

|

Sensor Implementations Results

|

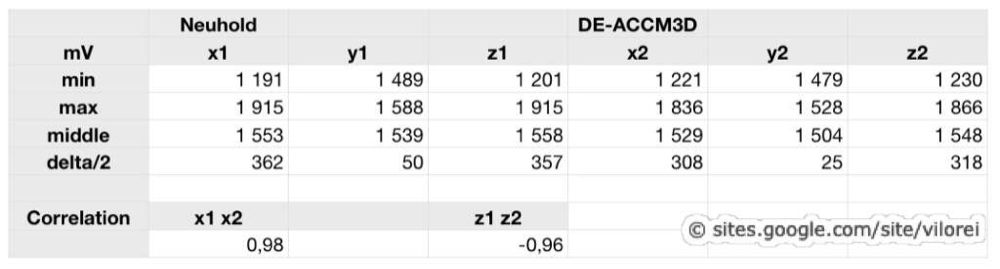

To compare the two implementations of the same sensor, I use the linear model basic correlation coefficient.

|

|

Results are excellent.

Both implementations of the sensor are consistent. The y-axis (y1 and y2) wasn't tested on the model, so figures and non significant. |

Previous |

Next |